|

737NG驾驶舱风挡玻璃温度传感器处的裂纹很普遍,如果平时检查没注意或者不知道手册标准,被机组发现后很容易造成延误。之前也有人回答过相应的标准,下面简单总结一下。

某737-800飞机,航前发现右1号风挡加温传感器处有裂纹:

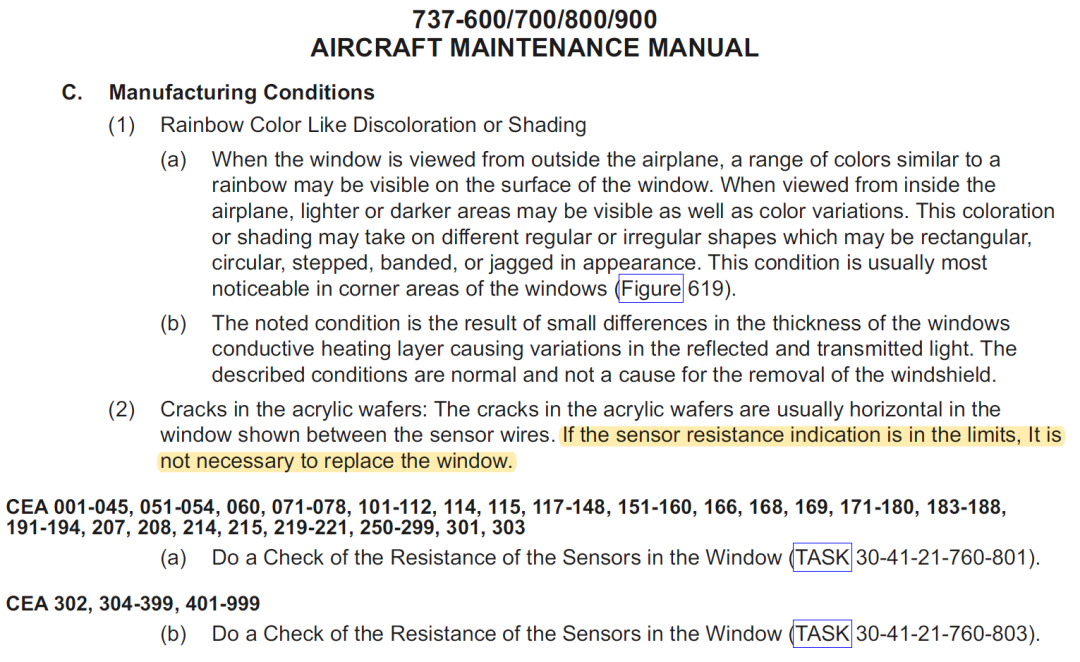

依据AMM56-11-00-200-803 Item 2.C(2):

只要传感器阻值正常,不需要更换风挡。参考AMM 30-41-21-760-803检查传感器阻值正常后飞机放行,航班延误。

某737-700飞机滑出时,机组发现右1号风挡边缘局部有疑似玻璃裂纹现象,出于安全考虑后滑回。

▲从外部拍摄照片

▲从内部拍摄照片

经机务现场详细目视及内外表面触摸检查,判断为风挡玻璃上包裹温度传感器的丙烯酸晶片的裂纹,不影响风挡的使用。

事件中出现裂纹的部件叫Acrylic Wafers,丙烯酸晶片。参考AMM手册中的描述:

1号风挡,AMM TASK 56-11-00-200-803:

2号风挡,AMM TASK 56-12-11-200-801:

Acrylic Wafers:Acrylic Wafers are used to hold the temperature sensor wires in position.The sensor pack consists of acrylic wafers that attach the filament wires to stabilizes the wire grid and lets the part be moved while being made.

丙烯酸晶片:丙烯酸晶片用于将温度传感器导线固定在位。传感器由丙烯酸晶片包裹,该晶片连接到细丝状导线上让其稳固成形,从而使传感器在制造时能移动。

知道了丙烯酸晶片的作用,也就不难理解手册的标准只要传感器阻值正常就行。

手册里也将这个归类在制造工艺情况(Manufacturing Conditions)里了。

维护提示

在包裹传感器的丙烯酸晶片出现裂纹后,随着使用时间裂纹也会逐渐增多。

之前有工程师也咨询过厂家:

Cracks in the acrylic wafers

Is it acceptable to check the sensors resistance just once to make sure the sensor is in good condition, or the check needs to be done repeatedly?

B has seen similar reports of this condition from operators over the years and are not aware of any sensor failures caused by this condition. There is no need to perform repeated checks of the sensors as a result of this type of cracking.

Is the cracks in the acrylic wafers a normal condition produced by the window manufacturing, or it is a kind of defective crack produced after the window manufacturing?

The specific root cause for this type of cracking is not known, but has not been seen on new windows, only windows that have been in service.

当发现固定驾驶舱风挡温度传感器细导线的丙烯酸晶片有裂纹后,只需要测量传感器阻值正常并做好记录就行,后面不再需要重复测量阻值:

提醒平时航后注意此处的检查,如果裂纹,注意填写好检查记录和相应风挡的件序号并报告给工程师进行记录。

除了维修人员和工程师掌握此处裂纹的标准外,同时也要注意与机组的沟通和交流,使机组知晓这一缺陷并不是风挡裂纹,对正常风挡加温使用和安全没有影响。

|